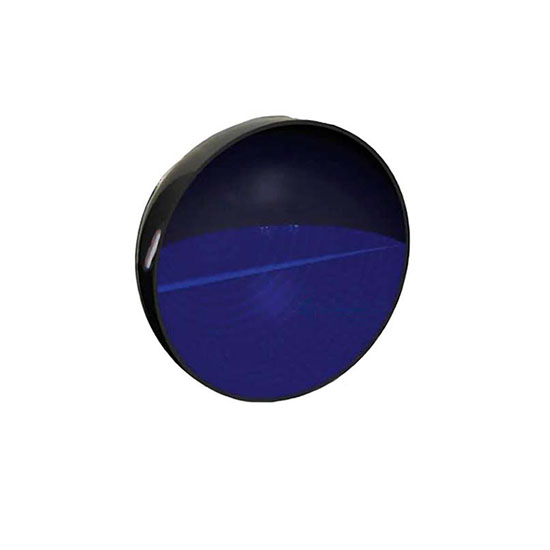

Diameter size: 100mm

Product descripiton: Water filled cover balls ( Water filled shade balls ) is made of food grade high-density polyethylene material and Anti-UV stabilizer by blow molding and 50% water injected, the surface unsmooth and black colored. Used in environmental protection, Control of vapor evaporation and control birds.

Packing: in standard plastic woven bags

MOQ: 50,000 pieces

Note: we accept customized the ball color, ball weight, ball size and package modality

Payment: T/T or L/C at sight

High-density polyethylene(HDPE) data sheets:

Properties | Typical Value | Unit | Test Method |

Mass density(23℃) | 0.954 | g/cm3 | ISO 1183 |

Melt Flow Rate (1900C/5.0kg) | 1.2 | g/10min | ISO 1133 |

Melt Flow Rate (1900C/21.6 kg) | 2.3 | g/10min | ISO 1133 |

Stress at Yield | 26 | MPa | ISO 527 |

Flexural Creep Modulus (4point, 1min) | 1300 | MPa | DIN 19537-2 |

Tensile Modulus (230C, v = 1mm / min ,Secant) | 1250 | MPa | ISO 527 |

Stress at Break | 32 | MPa | ISO 527 |

Elongation at Break | >600 | % | ISO 527 |

Elongation at yield | 10 | % | ISO 527 |

Softening Temperature | 77 | ℃ | ISO 306 |

Brittle Temperature | < - 80 | ℃ | ASTM D746-72 |

Shore D hardness | 62 | - | ISO 868 |

ESCR in Full Notch Creep Test (800C, 2% Arcopal ) | 5 | 3.5MPA | ISO CD 16770 |

Impact strength (230C) | 10 | Kj/m2 | ISO 179/1eA |

Swell ratio | 120 | % | Internal |

The above data are typical laboratory average. They are intended to serve as guides only. | |||